Rotor Resistance Tester

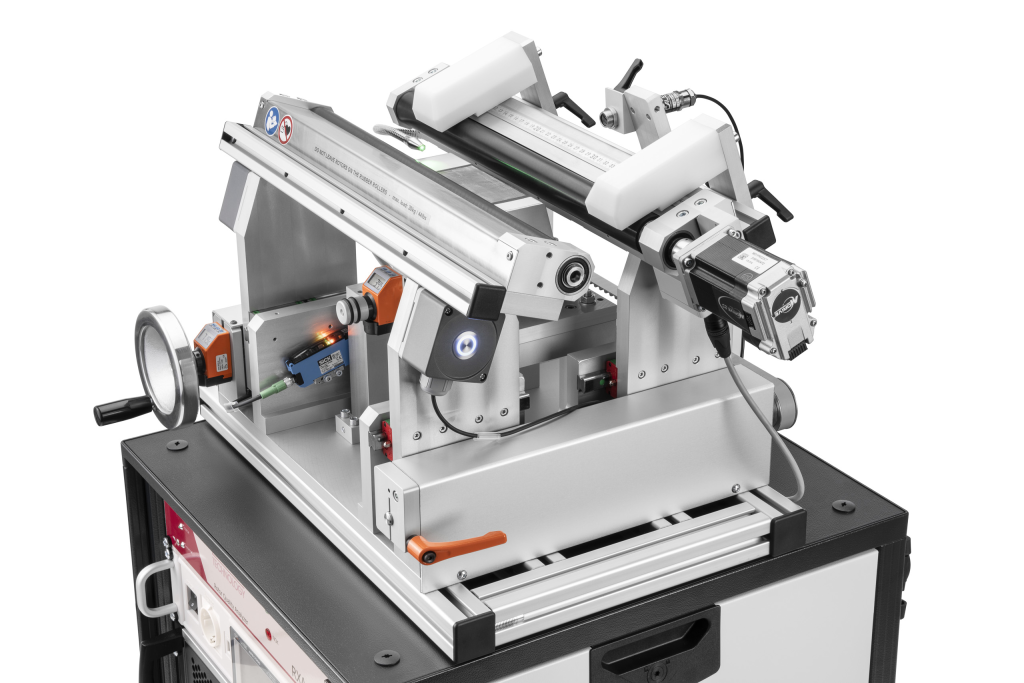

The RQA 300/RTS-3 Rotor Quality Analyzer is a very flexible testing system for testing of die-cast, brazed or welded aluminum and copper rotors for laboratory or industrial environment.

This unique desktop test system is especially designed for rotors for automotive applications and for the first time enables the measurement of rotor resistance of different size rotors without rotor specific accessories.

Features:

- New testing technology for die-cast, brazed or welded rotors.

- Suitable for aluminum and copper rotors.

- Advanced adjustable test station with digital indication for all mechanical adjustments.

- Fully automatic test and evaluation based on preprogrammed tolerances.

- Wide range of rotor sizes with no need of special tooling.

- For rotors equipped with or without shaft.

- Quick and easy adaption to different rotor types and sizes.

- Easy loading with adjustable rotor guides.

- Cycle time approx. 30 sec. enables 100% test of production lots.

- Possibility to connect to LAN system for saving data and statistical evaluation.

- Possibility to export test data.

- RQA Win Software for Windows 10 with extensive package for statistics and zoom.

Detectable faults:

- Broken or interrupted rotor bars.

- Badly soldered, badly welded or missing connection of bar to the end ring.

- Porosity either in the end rings or the rotor bars due to faulty injection processes, inferior aluminum alloy quality and/or gaseous contamination.

- Deviation of the rotor bar angle (skew).

- A short circuit between two or more rotor bars (fining).

- Eccentricity problems.

- Material inconsistencies in the aluminum alloy.

- Material inconsistencies in the steel core.

For more information please contact us.