All our Rotor Quality Analyzer´s are supplied with our RQA-Win Software for Windows®.

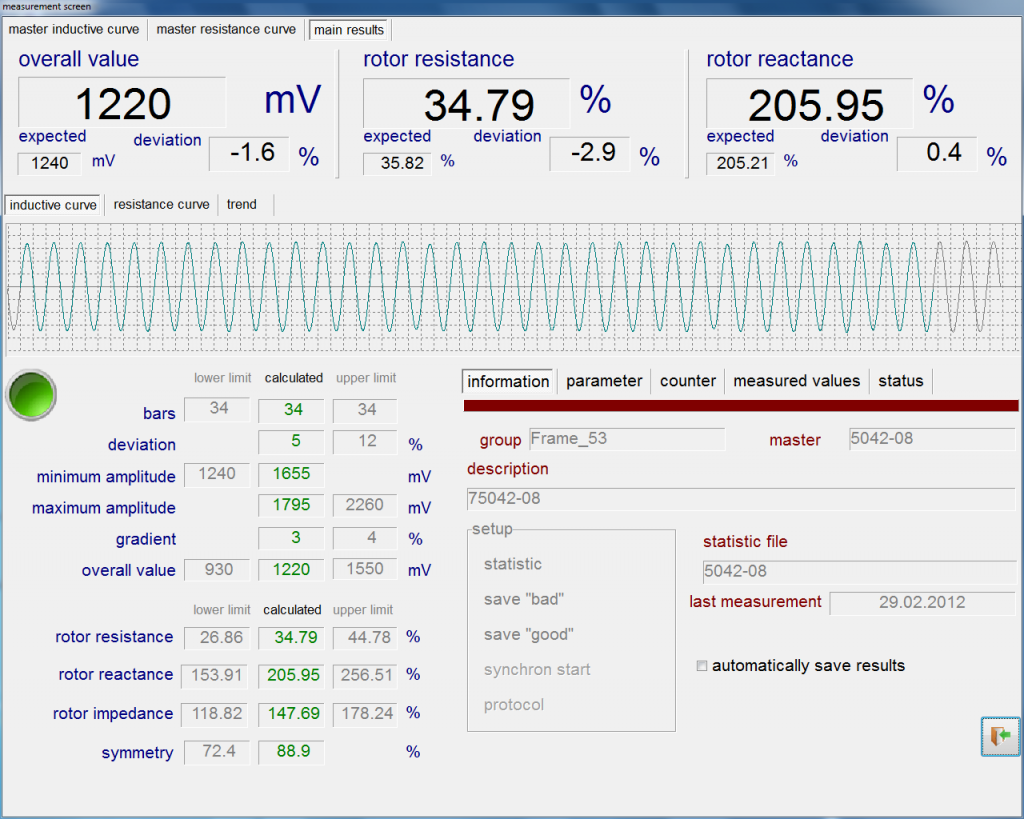

- User friendly menu-driven software for automatic Accept/Reject evaluation of rotors according to user selected parameter tolerance levels.

- Automatic set-up of all measurement and evaluation procedures (parameter tolerances) via the selection and retrieval of the Master Parameter File (reference rotor).

- Automatic learn feature to establish new Master Parameter Files for additional type of rotors to be tested.

- Automatic fault classification into different error types.

- Integrated counter for the total number of tested and failed rotors, and a complete record of the specific type and frequency of fault errors is recorded.

- Complete statistics package to facilitate a complete and thorough analysis of both rotor quality and productions capability.

- Interactive parameter tolerance functions via a “what if” approach in combination with the present and recommended

Cp and Cpk values. - Zoom function for rejected rotors automatically records all measurement results including the inductive/resistance waveform for more thorough analysis of the fault mechanism.

Rotor Quality Analyzer

Rotor Quality Analyzer